AOBO Insertion Rubber Sheet

The AOBO insertion rubber sheet/ fabric reinforced rubber sheet is a composite material made of rubber and cloth bonded by high temperature and high pressure or hot vulcanization technology. This structure makes the rubber sheet have the elasticity and wear resistance of rubber and the strength and stability of cloth.

AOBO provides you with a variety of insertion rubber sheets to choose from or can customized according to your specific needs. If you don’t know how to choose, please rest assured that our professional sales staff will give you the most professional advice. AOBO has a professional engineer team, a passionate sales team, and a perfect after-sales service team. AOBO will provide you with one-stop service.

If you are interested, contact us now.

Advantages of AOBO Insertion Rubber Sheet

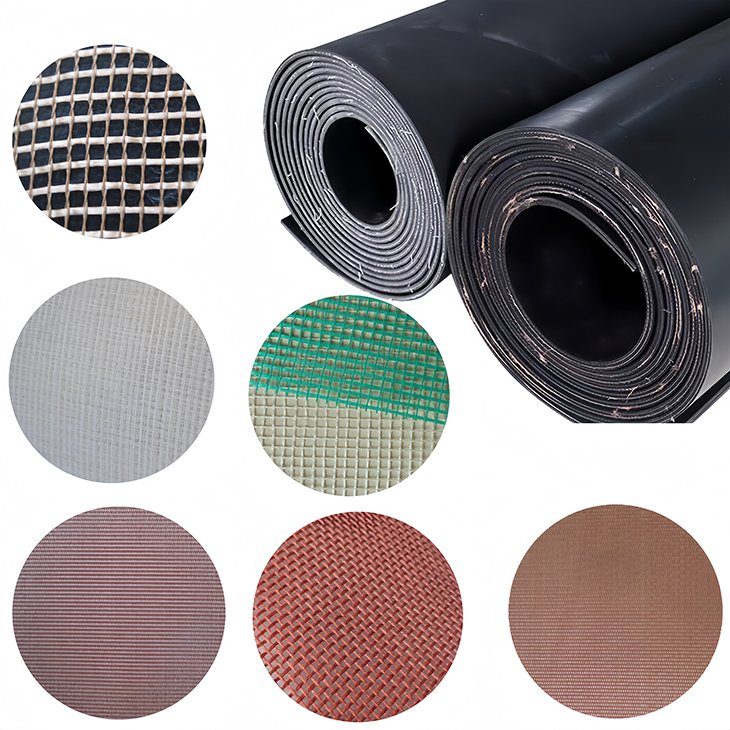

- AOBO can provide you with a variety of fabrics to choose from: cotton gauze, mesh red cloth, large mesh cloth, sub-mouth cloth, EP cloth, steel wire or iron plate, etc.

- Thickness 1.5-50mm, Width 0.1m-2m, Length 1-50m in rolls or cut length.

- Rubber material can be SBR, SBR/NR CR, EPDM, NBR, FKM and so on.

- Both sides shiny smooth surface, or both sides fabric impression, or one side shiny smooth, the other side fabric impression.

- AOBO insert rubber sheet has good tensile strength and tear resistance, good durability, and can withstand medium pressure, and small deformation, in addition to good cushioning and shock absorption effect. It can withstand extreme working pressure and wear conditions to ensure long-term stable operation.

AOBO How to Control the Insertion Rubber Sheet Production Process

The production process of rubber sheets mainly includes the following steps:

- Material preparation, plasticizing, mixing, molding, vulcanization, finishing, quality inspection.

- Each process has different requirements for the product, and each process is combined with a number of auxiliary operations.

- There are three key factors in the production of insertion rubber sheets: Vulcanization time, vulcanization temperature, and pressure.

- AOBO has special people to control the vulcanize temperature, and professional people to control the press and time according to different products.

Application Scenarios of AOBO Insertion Rubber Sheet

AOBO insertion rubber sheet is widely used in many industrial fields due to its unique performance advantages.

AOBO insertion rubber sheet has the characteristics of high strength and wear resistance, so it is used for seals, gaskets, cushions, etc. in mechanical equipment, providing good sealing effect while effectively protecting the equipment. In addition, AOBO insertion rubber sheet can also be used to make waterproof, shockproof, and soundproof materials in building structures, gaskets, seals, and pipe linings in chemical equipment.

For insertion rubber sheet, usually there are 1 layer of cloth, 2 layers of cloth, or 3 layers of cloth.

Yes. In outdoor environments, whether in harsh weather conditions or frequent mobile use, the Garment Rubber Sheet can maintain stable performance and appearance.

- First, you need to prepare the two raw materials, rubber and cloth.

- The choice of rubber is usually determined according to the use environment and needs, which can be natural rubber, nitrile rubber, chloroprene rubber, etc. The choice of cloth is more diverse, which can be various types of fabrics such as polyester, nylon, cotton, etc. These fabrics have their own advantages and characteristics and can be selected according to actual needs.

- The process of bonding rubber and cloth requires a special adhesive-adhesive. There are many types of adhesives, including solvent-based, emulsion-based, hot-melt-based, etc. When choosing an adhesive, you need to consider factors such as its compatibility with rubber and cloth and the bonding effect. Generally speaking, emulsion-based adhesives are more suitable for the production of cloth-added rubber sheets.

- With the right rubber, cloth and adhesive, you can start making “cloth-added” rubber sheets. This process needs to be carried out under high temperatures and high pressure to ensure that the bonding between rubber and cloth is firm and uniform. Specifically, the rubber and cloth coated with adhesive are stacked together, and then placed in a mold and heated and pressurized. Under the action of high temperature and high pressure, the rubber will soften and fit tightly with the cloth to form a new whole. Finally, after cooling, shaping, cutting, and trimming, we can get the “cloth-added” rubber sheet we want.